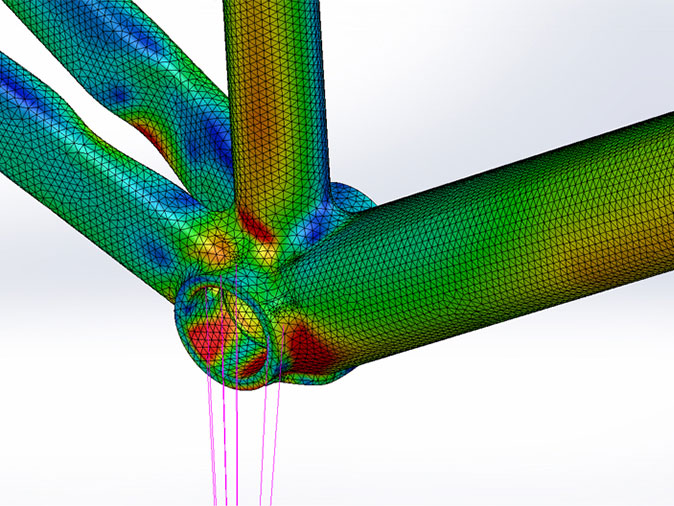

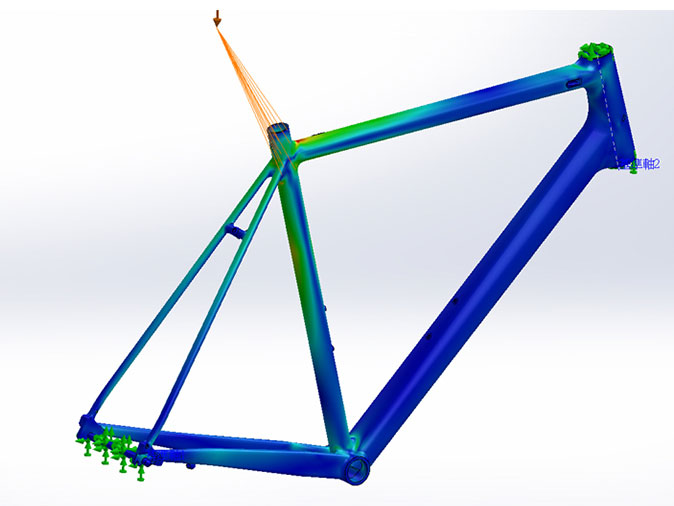

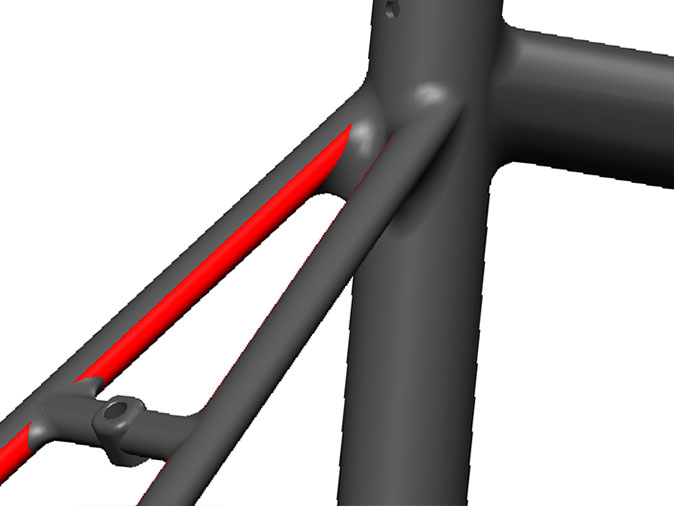

Under ISO 4210 standards, numerical analysis and simulation tests are used to test frame stiffness and durability. Using these testing protocols, any frame defects can be predicted enabling designs to be improved before production. This not only ensures frame safety, stiffness and durability, it also shortens verification time.

Customization Service

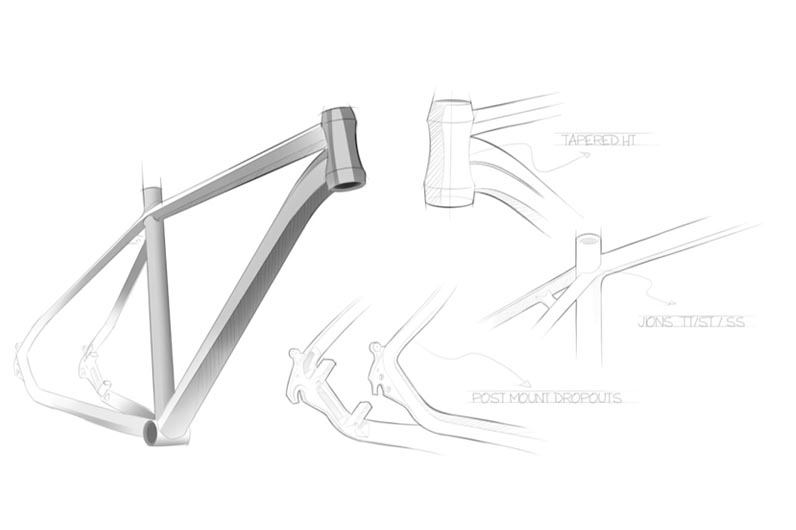

Understanding the needs of customers and target markets are the two secrets of a successful product design. By offering specifications that satisfy specific customer and market needs, both product expectation and brand image can be realized.

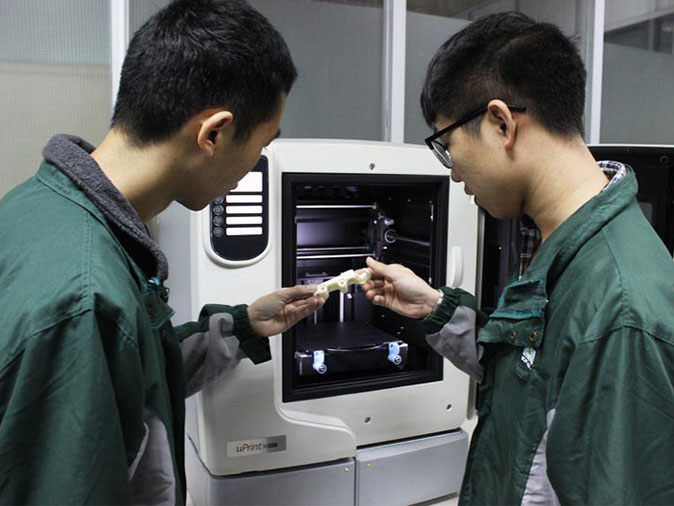

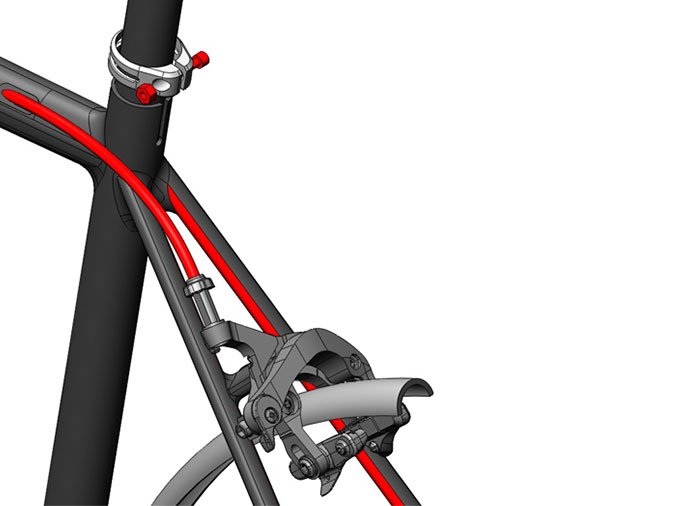

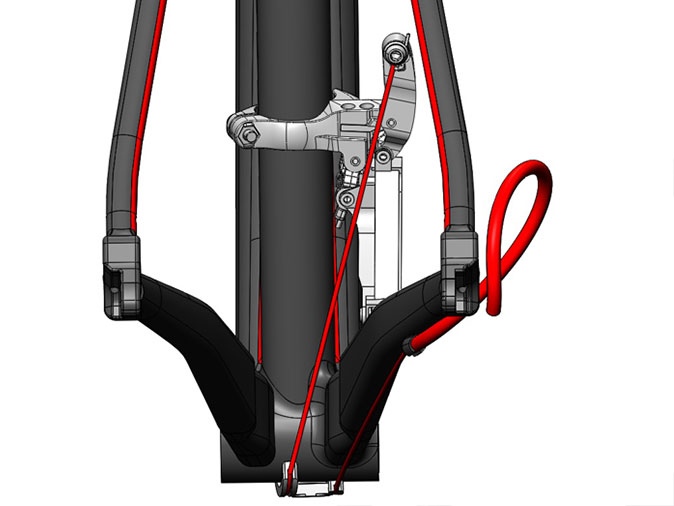

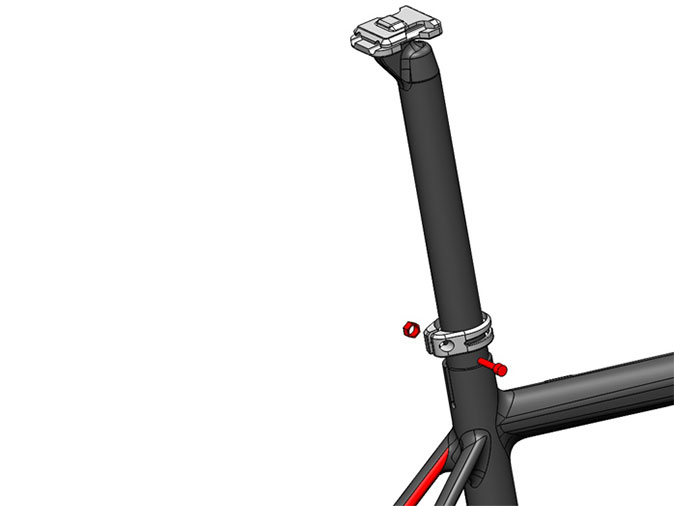

The Ideal R&D team has the technology to design a frame via 3D printing to ensure components are compatible and fit properly. This technology minimizes R&D waste and product defects.

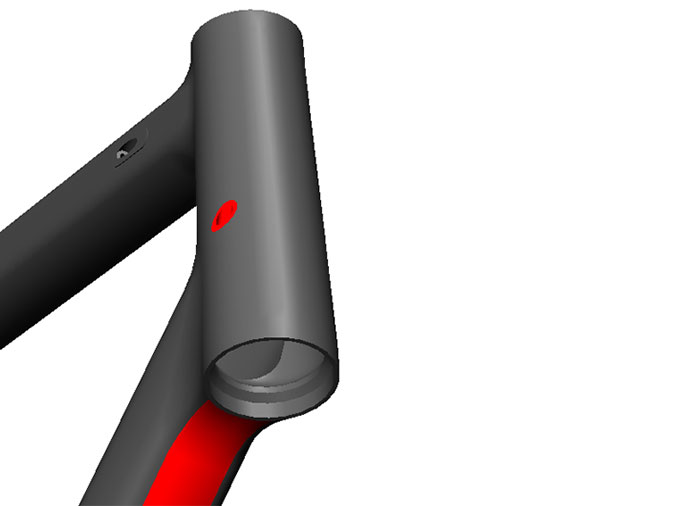

Ability to create unique frame and fork shapes to ensure that the bike's appearance matches with your company's brand and image.

Bike models are built using 3D printing software. These models help verify the integrity of the frame and its appearance before mass production. Not only does this create better communication between design and production, it also lowers production costs.